CFLE1011MW0 Frigidaire Washer Dryer Combo - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Squeaking

Watched Video Provided. Very Simple Repair. Asked my lovely wife to hold drum in place while replacing drive belt. She gladly complied and is back doing what she seems to love most. And no, I'm not kidding. Our washer and dryer seem to run 24/7/365. I've completed various repairs on both appliances over the last couple of years and saved 100's of dollars thanks to this site .

Parts Used:

-

David from PORT CLINTON, OH

-

Difficulty Level:Very Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Rear Bearing wearing out

I first looked at your directions then felt I could do the repair. So I ordered the part. The video was extremely helpful and allowed me to follow each step in the process. Last time I paid $270 for the exact repair. This time I costs me under $30. Plus I was able to clean out the entire inside of the dryer. The sitr instructions were very helpful and on target for any level of experience. I fixed my own dryer and saved a ton on it! Thank You, Randy In Colorado

Parts Used:

-

Randy from CENTENNIAL, CO

-

Difficulty Level:Really Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers, Socket set

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

lack of heat

Remove top lid by pushing tab on either side with a putty knife. Disconnect the 2 wire carriages on right. Remove one

phillips head screw on each side that holds front panel to dryer body. Remove front panel by using flat head screwdriver to pry panel from body. Remove thermostat located on bottom right attached to front of motor on a plastic body by removing two phillips head screws. Disconnect wires and place on new part.

phillips head screw on each side that holds front panel to dryer body. Remove front panel by using flat head screwdriver to pry panel from body. Remove thermostat located on bottom right attached to front of motor on a plastic body by removing two phillips head screws. Disconnect wires and place on new part.

Parts Used:

-

Ann from WALLA WALLA, WA

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

quit heating

The repair went smoothly considering I am a rookie. The repair videos on your site are great. Followed the techs instructions and got thru it fine.

Thanks,

Jim

Thanks,

Jim

Parts Used:

-

James from ALBUQUERQUE, NM

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The water would not completely drain and go to spin cycle and noisy while trying to drain.

I ordered pump so I would have it on hand. I didn’t want the washer in pieces waiting on parts. New pump came in 2-3 days with standard shipping. Found a video online for this model. Removed top. Removed control panel and set on front edge of frame. Removed door seal spring. Removed front panel and separated seal from drum. Pump located at bottom left. Removed pump screws. Got a shallow pan from kitchen to catch water. Removed hoses and trap. Not much water. Took trap boot and pump to sink for cleaning and found a bra wire had made it past the screen and was rubbing on pump impeller. That was the noise. Cleaned and reinstalled old pump. Has been running for 2 months without a problem. Easily returned the new pump! Highly recommend this company and site. Will come here for my repair jobs first. Hope I remembered all the steps correctly since it has been over 2 months.

Parts Used:

-

Tim from DEFIANCE, OH

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Top hinge on clothes dryer separated, leaving door difficult to open/close

Ordered part from partselect.com. Part was back ordered; however they were very proactive in communicating status updates! When it arrived it was simply a matter of removing door using a philips screwdriver, installing the new hinge and presto - job complete! Kudos to partselect.com ??

Parts Used:

-

Robert from CUMMING, GA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer lint filter was all torn up after 12 years of use.

Simple: I ordered the part from you then took out the old old and inserted the new one. Took all of 1 minutes

Parts Used:

-

Michael from DUNN, NC

-

Difficulty Level:Very Easy

-

Total Repair Time:Less than 15 mins

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The drive belt snapped due to age

Removed front and back panels as well as the dryer front, placed belt on drum and drive motor. I found that taking the door off the dryer front made the reassembly much easer.

Parts Used:

-

Thomas from MAYODAN, NC

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Pliers, Screw drivers, Socket set

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Broken Belt

As instructed by a Frigidaire Video for a Laundry Center: FIRST disconnect the power I then removed the access panel, Safety Shield was missing (previous Serviceman never replaced), Entire door assembly and the top cover. Doing this exposed the entire Drum and made installation VERY easy. Always research your job as there are many reliable videos instructions available, it takes the fear and guess work out and leaves only confidence ahead. I am 63 yrs old and if I can attempt this anyone can!

Parts Used:

-

Patricia from FARMINGDALE, NJ

-

Difficulty Level:Very Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Squeaky drum until drum would not turn.

Watched on-line video, then applied those steps.

1. Pop the front of the deck loose using putty knife to depress clips;

2. Disconnect wires from light and door switch;

(Before I disconnected wires from door switch and light, I made wiring sketches to make sure I reconnected in original manner.)

3. Remove lint filter mount screws and mount from bottom of door opening;

4. Cut drum belt with wire-cutters and removed it;

5. Remove drum support clip from top center of front panel;

6. Remove (1) screw from each side of dryer body that hold front to sidewalls, removed front panel;

7. Remove drum by lifting the rear out of the bearing, then moving it forward through the machine front;

[While I had the dryer disassembled, I thoroughly cleaned it of lint, dirt & metal filings. The metal filings were from the worn ball hitch and drum support bearing cup. I spent as much time cleaning it out as I did working on it.]

8. Stand drum on gallon paint bucket while removing ball hitch (Use a #2 drywall phillips apex to obtain sufficient seating & torque to remove and reinstall ball hitch screws at rear of drum.);

9. Have a second person hold the new ball hitch in position while starting screws, if necessary;

10. Use nut driver w/5/16" socket to remove bearing retainer & ground ball clip;

11. Install new bearing into retainer clip, insert attachment screws through the holes in both, stick grounding ball in depression on back of bearing as screws are fed through back panel;

12. Hold ground ball clip in place to start one screw, then the other & tighten with nut driver;

13. Start drum belt on motor shaft and position against tensioner pulley;

14. Feed drum through front of machine and loop belt over rear of drum;

15. Slide belt forward on drum as drum moves to rear to keep it aligned with position of tension pulley;

16. Lift rear of drum to place ball hitch on top of bearing, then press down to seat it into bearing;

17. Turn drum to ensure belt alignment, then re-accomplish steps 6 thru 1.

1. Pop the front of the deck loose using putty knife to depress clips;

2. Disconnect wires from light and door switch;

(Before I disconnected wires from door switch and light, I made wiring sketches to make sure I reconnected in original manner.)

3. Remove lint filter mount screws and mount from bottom of door opening;

4. Cut drum belt with wire-cutters and removed it;

5. Remove drum support clip from top center of front panel;

6. Remove (1) screw from each side of dryer body that hold front to sidewalls, removed front panel;

7. Remove drum by lifting the rear out of the bearing, then moving it forward through the machine front;

[While I had the dryer disassembled, I thoroughly cleaned it of lint, dirt & metal filings. The metal filings were from the worn ball hitch and drum support bearing cup. I spent as much time cleaning it out as I did working on it.]

8. Stand drum on gallon paint bucket while removing ball hitch (Use a #2 drywall phillips apex to obtain sufficient seating & torque to remove and reinstall ball hitch screws at rear of drum.);

9. Have a second person hold the new ball hitch in position while starting screws, if necessary;

10. Use nut driver w/5/16" socket to remove bearing retainer & ground ball clip;

11. Install new bearing into retainer clip, insert attachment screws through the holes in both, stick grounding ball in depression on back of bearing as screws are fed through back panel;

12. Hold ground ball clip in place to start one screw, then the other & tighten with nut driver;

13. Start drum belt on motor shaft and position against tensioner pulley;

14. Feed drum through front of machine and loop belt over rear of drum;

15. Slide belt forward on drum as drum moves to rear to keep it aligned with position of tension pulley;

16. Lift rear of drum to place ball hitch on top of bearing, then press down to seat it into bearing;

17. Turn drum to ensure belt alignment, then re-accomplish steps 6 thru 1.

Parts Used:

-

Doug from ODESSA, TX

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Loud squealing when dryer was turning. At first it was just when it started and eventually it was constant.

Be carful when unpacking, the grounding bearing is in loose with the bolts. I had to chase it. Follow the video instructions for the stacked washer/dryer combo and you will not have a problem. Recommend you have two people working to lift the drum out and to install the new bearing.

Parts Used:

-

Eric from GRANBURY, TX

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Socket set

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

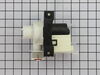

Leaking drain pump

Replaced drain pump using this walk through. Different models, but pretty straight forward.

Parts Used:

-

Michael from MEDFORD, OR

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

lack of heat

-

ann from WALLA WALLA, WA

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer did not drain, would not cycle; pump was 'humming' and not moving water

Remove front lower access panel: two phillips screws at the lower edge then the panel slid down and off. Removed 5/16 pump mounting screws then slid a shallow pan under pump to attempt to catch stale water, removed left side (inlet) hose clamp and wiggled hose off to drain water with some success, some spillage. Removed outlet hose, turned the pump around to remove electrical connection. Reversed steps to mount new pump and after fighting with spring clamp on outlet side I chose to replace that spring clamp with a 1 1/2" stainless hose clamp which then could be tightened with a screwdriver and only took a minute to wrap up.

Parts Used:

-

DANIEL from PINCKNEY, MI

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

LINT FILTER

-

ANGEL from MIAMI, FL

-

Difficulty Level:Very Easy

-

Total Repair Time:Less than 15 mins

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!