CFLE1011MW0 Frigidaire Washer Dryer Combo - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Latch on dryer no longer worked

So easy! I ordered the part on the website. Received it 24 hours later. And popped it in place. Good as new.

Parts Used:

-

chris from dallas, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

dryer would turn for about 1min then stop

I replaced the rear bearing assy. Thanks to all that sent in there stories. very helpful. But my problem was the breaker in breaker box. needless to say "check your outlet for proper voltage.First,before anything else." i had a bad breaker, had it replaced,with proper 30amp fuses.Dryer works fantastic..Thanks to all again for your input. Great Website...

Parts Used:

-

James from Fort Worth, TX

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer making horrible squeaking sound when running

I am a "do-it-yourselfer" despite my husbands opposition. I followed instructions from one of the posts on the site and took apart the dryer. I found the location of the rear bearing and took it out and replaced it with the new one. Easy as that. Made sure the parts looked the same. Made sure I saw how everything went together. I used a magnet to hold the ball bearing in place on the rear mount and taped the metal bracket on the outside of the dryer. Screwed it right in. Reassembled in reverse and works like a charm. To all the women out there who don't think they can do this. It's easy. Give it a try.

Parts Used:

-

SHARON from SUMMERVILLE, SC

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers, Socket set, Wrench set

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

bearing bad and shaft broken

replaced bearing and shaft new belt and everything works just fine

Parts Used:

-

Randall from New Roads, LA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

3 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Making a squiking noise and letting lint into the cavity of the dryer

pulled appliance away from wall and unplugged the electrical cord and then used putty knife to pop up the top. Then removed the screws that held the front in place. Disconnected the wire to the switch on the door and then front on a rug and used acetone and scraper to remove the old glue and felt. Cleaned the area thoroughly and apply the glue that come with the kit an give it a couple of seconds to get tacky and then applied the felt and used clothes pins to hold in place for about an hour and then put back together and let it set over night before using. Had good success and it solved my problem.

Parts Used:

-

Robert from Rice Lake, WI

-

Difficulty Level:Really Easy

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Our door catch got lost inside the dryer after the door was slammed to hard

I took the new door catch out of the packaging and just snapped it in place it was easy peasy and took less time than opening the package

Parts Used:

-

Joyce from PORTAL, GA

-

Difficulty Level:Very Easy

-

Total Repair Time:Less than 15 mins

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

High pitched squeal from dryer during use...

Followed directions of another website...had to replace ball and socket joint that attached the drum to the back frame of the dryer...removed top outside metal cover of dryer to facilitate attaching ball/socket kit to the drum...this allowed us to secure the ball/socket kit to the drum without cross threading the screws...with the top of dryer removed this allows you to lift the drum to fit into the plastic bracket...dryer had been in use for over ten years before repair...extreme amount of lint debris throughout internal area of dryer...lint was everywhere...spent a large amount of time vacuuming lint...duct connection from lint trap to lint fan/impeller was very loose and over the years lint seeped out from connection...suggest using duct tape or wood/composite shims to hold the lint duct to the fan/impeller...make sure you remove lint from the back of drum crevice and around the area of the heating element for electric dryers...for sanity's sake this should be a two person job...for this repair we replaced the upper and lower drum felt strip, installed a complete and new ball/socket kit, replaced drum belt, and vacuumed and damp wiped the entire interior of the dryer...

Parts Used:

-

Robert from OCEAN SPRINGS, MS

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Screw drivers, Socket set

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Lint was going everywhere. The new one fits perfectly, but lint is still going alll over

-

Christine from DEER PARK, NY

-

Difficulty Level:Very Easy

-

Total Repair Time:Less than 15 mins

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer drum not spinning

This link provides clear simple instructions which I was able to use successfully.

Parts Used:

-

JAY from WESTON, FL

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

dryer stopped in middle of cycle and would not restart

followed the repair video and replaced thermal fuse and thermostat(recommend replacing both due to the problem could of resulted in either part being the cause),Repair went relatively easy.I also recommend to clean and vacuum the dryer while you have it all apart due to a lot of lint buildup and don't forget to unplug before servicing!Stay Safe!!!

Parts Used:

-

MICHAEL from HUDSON, NY

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Drum belt and bearing needed to be replaced.

Unplugged dryer, removed access panel on the back of dryer. Removed access panel on the front of the dryer. Removed the front panel of the dryer. Inside the drum, removed the three screws on the center bearings. Slide the bearing out of the bearing support. Replaced the bearing support. Then reassembled the drum. Replaced the belt an reassembled the dryer. Two people would be recommended for reassembly.

Parts Used:

-

Troy from GOTHENBURG, NE

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

load squeal

replaced rear drum bearing kit. Watched video made it real easy. The only problem was getting the belt back on the pulleys.

Parts Used:

-

Mark from HGHLNDS RANCH, CO

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

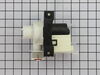

Impellar was broken on the washer drain pump.

Removed front panel and unplugged wire connector to drain pump. Loosened two hose clamps and removed hoses the unbolted drain pump from washer frame. Simple removal and even simplier installation of new drain pump.

Parts Used:

-

Michael from IOWA PARK, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer making metal on metal noise....

Just like in the video, but with a stackable washer/dryer unit, works like new now....

Parts Used:

-

James from RACINE, WI

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Noisy

Took it apart and installed the parts. Then I threw the dryer in the trash and bought a new one.

Parts Used:

-

April from CARYVILLE, TN

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!