41790812992 Kenmore Washer Dryer Combo - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Dryer heater broken

Removed top cover.

Lowered control assembly.

Removed front door assembly.

Removed drum.

Removed heater assembly.

Removed support bearing and bracket using existing bonding ball.

Re-assembled in reverse order.

Lowered control assembly.

Removed front door assembly.

Removed drum.

Removed heater assembly.

Removed support bearing and bracket using existing bonding ball.

Re-assembled in reverse order.

Parts Used:

-

Johnny from PINEBLUFF, NC

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Agitation weak

Got the washer used. Agitation was okay, but the screw part of the agitator was very weak and kept slipping, so bought a replacement agitator. This DID NOT fix the problem, it remained the same. Watched a video on this site about the part under the agitator, whereupon we saw there was supposed to be a washer on top of the spike-thing where you screw the agitator down. THAT was the problem. That washer was missing, and when we replaced it, the agitation was fixed! Very much appreciate this site.

Parts Used:

-

Linda from WEST POINT, GA

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

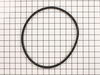

Leaking through the main tub seal

-Remove front panel - 2 screws

-Remove the top panel - 2 screws

-Disconnect the lid switch from the top panel - 2 screws

-Remove the agitator cap - unscrew

-Remove the agitator - This was a bit difficult and required a lot of jiggling but it eventually came off

-Remove the inner drum - 5 bolts at the bottom

-Remove the drum mount - 2 bolts and then it got really difficult. A lot of penetrating blaster, wire brushing, jiggling, and some strategically placed hammer taps (don't damage the threads.

-Remove the seal

-Clean up the inner and outer seal seating surfaces

-Rinse and repeat in reverse (pun intended)

-Remove the top panel - 2 screws

-Disconnect the lid switch from the top panel - 2 screws

-Remove the agitator cap - unscrew

-Remove the agitator - This was a bit difficult and required a lot of jiggling but it eventually came off

-Remove the inner drum - 5 bolts at the bottom

-Remove the drum mount - 2 bolts and then it got really difficult. A lot of penetrating blaster, wire brushing, jiggling, and some strategically placed hammer taps (don't damage the threads.

-Remove the seal

-Clean up the inner and outer seal seating surfaces

-Rinse and repeat in reverse (pun intended)

Parts Used:

-

Rob from DACULA, GA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Screw drivers, Socket set

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

no filter

-

Luis from La Jolla, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

4 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Leveling Leg Broken

The leveling legs on my Frigidaire stackable washer & dryer were broken. They are made of plastic and while moving the unit one of the legs had broke off. I ordered two replacements from PartSelect and received them within a few days. The old legs were removed by screwing them out and then the new ones were installed. Pretty easy installation for DIY. The new legs work great.

Parts Used:

-

Brian from Rochester, NH

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Wrench (Adjustable)

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Front drum guidesnubber ring was worn out

removed the top of dryer, pulled front panel back from drum and installed snubber(Front Drum guide).

Parts Used:

-

Alan from Emporia, KS

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

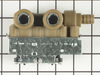

over filling

no problemO top loader. open top, disco two electrical plugs and a small hose, then remove two screws that hold valve in place and remove. Re install in reverse order. Thanks for your support Eliot in Alaska!

Parts Used:

-

eliot from fairbanks, AK

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

clothes were getting stuck

after numerous holes put in my families clothes i looked on line and found "partselect.com". i ordered the front drum glide after seeing a similar story about the clothes being torn and getting caught and my family and i have our new dryer back!! yeah :<)

Parts Used:

-

robert from lake worth, FL

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

4 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer tub was not spinning

Smelled burning rubber, checked belt. Belt was cracked and worn out. Easy repair. Removed front of the machine held together with two screws at the bottom of the unit. Removed top cover of machine (the part with the lid). It just pops off. Pushed tensioner wheel in and took off old belt. Putting new belt on was super easy. Working like a champ now. $20 total with shipping. Not too bad to save a washing machine.

Parts Used:

-

josef from Nashville, TN

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Loud Squealing

Remove top panel with large flat screwdriver and 2 screws in back.Remove bottom panel with 2 screws.Release belt tensioner and remove belt.Remove 3 screws in center of drum inside.Remove drum. Remove rear bearing by pulling up on assembly.Replace all parts in reverse order.

Parts Used:

-

William from Hudson Falls, NY

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer drive belt came off dryer drum several times.

Stud was coming off the motor cradle- bad swedge at the factory, Belt tensioner went on stud.

Removed small access panel in back. Remove tensioner and set to left. Remove inner and outer panels from the front of the laundry center to expose exhaust duct and blower. Loosen control panel and remove, disengaging four keyed plugs. Remove lint screen. Loosen two screws inside dryer to disengage exhaust duct and remove, Unscrew aproximately six screws and remove front half of blower. Remove clip from blower shaft, and cautiously pry the blower wheel off the shaft (this is the touchiest part of the job. Some force is necessary). Remove the back half of the blower housing by unscrewing the three screws exposed by the wheel (access through the front) and the standoff by the heat/moisture sensor (access through the back).

You have now exposed the motor. It is held on to the cradle with two clips. Remove the clips by putting your thumb on the clip above the hook and squeeaing while prying the end of the clip off with a screw driver. One clip is accessed through the back and one through the front. When the motor is loose unscrew the two screws through the back panel that keep the cradle in place. Pull it back and remove it, while holding the motor up.

Installation is the reverse. Make sure the new part matches the old part exactly. Make sure that the soft bushings on the motor are centered on the cradle before you clip it in place.

Removed small access panel in back. Remove tensioner and set to left. Remove inner and outer panels from the front of the laundry center to expose exhaust duct and blower. Loosen control panel and remove, disengaging four keyed plugs. Remove lint screen. Loosen two screws inside dryer to disengage exhaust duct and remove, Unscrew aproximately six screws and remove front half of blower. Remove clip from blower shaft, and cautiously pry the blower wheel off the shaft (this is the touchiest part of the job. Some force is necessary). Remove the back half of the blower housing by unscrewing the three screws exposed by the wheel (access through the front) and the standoff by the heat/moisture sensor (access through the back).

You have now exposed the motor. It is held on to the cradle with two clips. Remove the clips by putting your thumb on the clip above the hook and squeeaing while prying the end of the clip off with a screw driver. One clip is accessed through the back and one through the front. When the motor is loose unscrew the two screws through the back panel that keep the cradle in place. Pull it back and remove it, while holding the motor up.

Installation is the reverse. Make sure the new part matches the old part exactly. Make sure that the soft bushings on the motor are centered on the cradle before you clip it in place.

Parts Used:

-

David from Bayonne, NJ

-

Difficulty Level:Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set, Wrench set

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Broken Knob

I pulled off the old knob and replaced it with the new one. The part was very easy to find on your web site. Thank you

Parts Used:

-

Gary from Tyngsborough, MA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

3 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Lound noise inside dryer

1. unplug the dryer, remove the aluminum vent and move it to an area that has a lot of elbow room.

2. remove the top lid with a flat screwdriver. It seems that the top lid was being held by 2 metal clips on each end.

3. on the right hand side removed the 2 wires from the front face of the dryer. this is the switch for the open door sensor. remember which wire goes where.

4. the on the left and right side will be one screw and one metal clip, unscrew and pop the front panel with a flat screwdriver.

5. in front of the drum remove the plastic clip that is used as a guide for the drum to be in place.

6. look in the drum and there is 3 screws that form a triangle shape. remove the screws.

7. remove the belt from the drum. inspect the belt. replace if necessary.

8. lift up and pull out the drum.

9. remove the rear drum assembly and replace it with the new parts.

10. repeat in reverse and your done.

It took me 40 minutes the first time i replaced the rear drum assembly then i forgot to hook the belt up correctly and i unassemble the unit in 5 minutes fix the belt and assemble the unit in 5 more minutes. Now the wife is happy.

2. remove the top lid with a flat screwdriver. It seems that the top lid was being held by 2 metal clips on each end.

3. on the right hand side removed the 2 wires from the front face of the dryer. this is the switch for the open door sensor. remember which wire goes where.

4. the on the left and right side will be one screw and one metal clip, unscrew and pop the front panel with a flat screwdriver.

5. in front of the drum remove the plastic clip that is used as a guide for the drum to be in place.

6. look in the drum and there is 3 screws that form a triangle shape. remove the screws.

7. remove the belt from the drum. inspect the belt. replace if necessary.

8. lift up and pull out the drum.

9. remove the rear drum assembly and replace it with the new parts.

10. repeat in reverse and your done.

It took me 40 minutes the first time i replaced the rear drum assembly then i forgot to hook the belt up correctly and i unassemble the unit in 5 minutes fix the belt and assemble the unit in 5 more minutes. Now the wife is happy.

Parts Used:

-

Joseph from little Egg Harbour, NJ

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers

3 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Drive Belt Was Noisy-Slipping

I just popped up the top front using a large straight (slotted) screw driver, then removed the 2 screws at the bottom front, then the whole front panel popped down about a half inch to be lifted out of the way. I found the old drive belt way down under the motor (still attached as normal), very near the floor and removed the worn out belt by hand, and replaced it with the new belt by hand also. The spring loaded belt tightener- idler wheel makes this a very simple process to accomplish. Then, I replaced the front panel-- all done. Works like new.

Parts Used:

-

Steve from Carrollton, TX

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

3 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

No Heat, Dryer Runs, But Right Side Of Timer Would Not Advance, Left Timer Would

I used the percentage scale on this website to try and determine the likely cause. After reading several sites, I couldn't make sense of the timer not working on just one type cycle. When I got the dryer drum off, I could plainly see that one of the heater coils was broken. They get heat stressed and break down over time and a hard shake probably finished this off. This unit is 5 plus years old. It was Saturday and I had no heater, so I actually found it at a local parts supplier. Also replaced the drum bearing and the bearing cup in the rear along with the heater. BTW, a new heater comes with a HIGH thermal switch attached to it so don't buy it extra. The bearing cone also comes with a new bushing in the pack. I DID use the Thermal Limiter that I order from the site because I was already in there. Everything works great now. I may have gotten most off my parts elsewhere but this site was the biggest help of them all. I will definitely be back here again.

Parts Used:

-

STEPHEN from Nashville, TN

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!