41790812992 Kenmore Washer Dryer Combo - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Broken Door Strike

After the part arrived, I located a pair of needle nose pliers. Then removed the broken one and inserted the new one. It was very easy.

I also noted that the new part was of a better design than the original. It should not need further attention.

I also noted that the new part was of a better design than the original. It should not need further attention.

Parts Used:

-

William from Martinsville, IN

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers

9 of 17 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

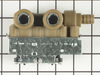

The water would not stop filling

First I did some research and concluded the water inlet needed replacing. Obviously once you know what you need you go to PartSelet.com for parts and installation info. I went through the front of the machine. So I removed the front of the washer(2 screws at the front bottom)slide down the panel to separate it, lifted the top cover of the washer(2 screws on the underside of the lid and 3 wire connectors to the fill switches) and then loosened the right side panel(3 screws at the bottom). Now pushing the wash barrel to the side it gave me enough room to squeeze my arms in to the inlet part. Be careful there are sharp edges and screw tips inside the machine. I removed the 2 wire connectors(hot and cold solenoids) inside the washer and then removed the screw from the back outside that holds the water inlet to the machine. Now I was able to pull the inlet closer to me so I could get pliers on the hose clamp to loosen and remove the old part. The new part was an improved version that was more solid. I attached the hose affixed the squeeze hose clamp and pushed the water inlet into place. The screws were not threading so I grabbed a couple of self taping hex head screws and a nut driver head for my drill and screwed the inlet in from the back of the washer. Then I replaced the wire connectors to the water inlet. With the water inlet complete, I reattached the right side panel, the washer lid, fill switch connectors and the front panel. Washer fixed and running perfectly!

Parts Used:

-

Jeff from Monticello, NY

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers

5 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer would not even turn on. Removed 2 screws holding thermal limiter switch and removed t

Basically, i followed instructions on 1 video i seen, but was able to shorten repair by not removing drum, and was still able to access the thermal limiter switch to remove old one and install new one. Worked like a charm. Thanks Dan

Parts Used:

-

Daniel from SAN ANTONIO, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

5 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Leaking hoses

I made my job difficult by removing the back panel, then the side, and finally discovered the front panel opens giving access to the washer. Using heavy pliers I removed the spring clamps and replaced the pump to washer hose and the other hose end to the tub. Turned on the washer no leak only to discover the drain hose had developed a leak. So I ordered the second hose. I was not sure how to release the plastic retaining clamps. Finally just yanked them loose, which worked. Ran the hose through the machine out the back into the drain pipe. I was able to reattach the retaining clamps put the spring clamp on the pump end of the hose. The difficult part was getting the back, sides and front of the washing machine together that took hours.

Parts Used:

-

Dixie from STRANG, OK

-

Difficulty Level:Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Pliers, Screw drivers

5 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Cloths not drying

Removed the back panel and the exhaust hose.removed the heater element and changed the thermostat wire was melted cut damaged part of wire soldered and rapped with black electrical tap

Parts Used:

-

keith from ELLENVILLE, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers, Screw drivers, Socket set

5 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

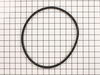

broken belt

I took off the front panel of the washer and placed the belt on the large tub wheel and then the smaller wheel. I placed the belt over the adjustable third wheel and turned the tub in order to get the belt all the way in the grooves. Thirty minutes max to replace. Thanks, my order was 100% satisfactory

Parts Used:

-

odell from Elizabethtown, KY

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

5 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

water leaked into machine when turned off

Removed top,removed hose from inlet valve to washer,removed hot and cold inlet hoses and with phillips screwdriver removed water inlet valve assy and replaced. Reassembled and tested.

My order arrived 2 days after i ordered same. Excellent service from partselect, Thank You....

My order arrived 2 days after i ordered same. Excellent service from partselect, Thank You....

Parts Used:

-

Henry from Frenchtown, NJ

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

5 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Filter Needed Replacing

-

Joe from Reston, VA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

6 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

drum glides worn out making thumping noise.

watched video on replacing rear bearing.although rear bearing was not the part(s) i needed to replace, video instructed disassembly procedures to get to the drum glides. this was a very simple and easy to follow video. repair was a breezeand took roughly 25 minutes. the most time consuming segement of repair was vaccuuming out lint,that was 15 minutes. In future, as a preventative, i plan to remove front of machine to clean annually.

Thank you.

Thank you.

Parts Used:

-

david from edinboro, PA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

5 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer bearing failure

From previous responses on this site. I just followed their lead. If I had not found these folks, and the responses, it would have been a nightmare. It looked like and I thought the dryer came apart from the back! But in reality it comes apart from the front!! Absolutely fantastic site and help. Fast shipping, I ordered on Wednesday before Labor Day, didn't expect the parts until the following Wednesday, but received the parts on Saturday morning, and had the dryer back running by Sunday AM. Never even ran out of clean clothes!!!!!

Parts Used:

-

Douglas Green from Kansas City, MO

-

Difficulty Level:Easy

-

Total Repair Time:More than 2 hours

-

Tools:Pliers, Screw drivers, Socket set

21 of 36 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

dryer door wouldnt close

the catch on the door was worn and cracked.... so I noticed it could be easily popped out with a screw driver and when the new part came in the mail 2 days later, it was just as easy to pop back in with no tools required. Now the door stays shut really good!!!

Parts Used:

-

karen from aurora, IL

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

5 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Zipper was cought between brum and cabnet

Disconect power, Removed top and front of dryer.

The broken zipper was easly removed at this point. The plastic glides easly snap out and in. The felt took some more time to scrape off and clean the old glue. Glue the new felt into place and replace front and top. The parts were shiped promptly and the dryer was out of service for only three days.

The broken zipper was easly removed at this point. The plastic glides easly snap out and in. The felt took some more time to scrape off and clean the old glue. Glue the new felt into place and replace front and top. The parts were shiped promptly and the dryer was out of service for only three days.

Parts Used:

-

John from Swansboro, NC

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

5 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The dryer was over-heating, the vents had been cleaned to it wasn't the vent, but something wrong with the dryer. The Thermal Limiter was a cheap try to see if it would fix the problem.

The hardest part was getting to the part and removing it and putting it back on. The schematics that you had on your website helped us locate where it needed to go and, hopefully, that will solve our problem.

Parts Used:

-

William from Pardeeville, WI

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Wrench set

7 of 12 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Drum guides came out into dryer

Removed old guides ( some of the snap in fastners were broken off). REplaced guides by rolling drum, easy to snap in @ drum bottom each time.

Parts Used:

-

lloyd from celina, OH

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

5 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

squeaking in dyer progressively got unbearable

removed top and front panel on stackable dyer unit. 3 screws at back of the inside of the drum, and the drum was out. installed new bearing and belt and all was good.

Parts Used:

-

matt from south vienna, OH

-

Difficulty Level:Easy

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Screw drivers

6 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!