LSE7800 - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Lid closes, switch wouldn't turn on machine.

Used toothpick for a year to push switch acctuator far enough to engage switch. Broke my foot and found time to order part thru PartSelect. Went from cast to boot and received part 2 days after ordered. Had difficulty with foot and getting to switch. Went back into PartSelect and figured out how to dis-assemmble panels thru the diagrams. Time on my job doesn't, just that their service and expertise that is available to everyone is there to use. Broken bones or not, I will always get my parts and advice from PartSelect. Thanks to PartSelect.

Parts Used:

-

Kenneth from Wilmington, IL

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers, Socket set

31 of 47 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer would quit before the end of the cycle

My wife reported that the dryer was not working. I checked it and it seemed to work fine. This went on for about a month or two. Every time I checked it, it started just fine.

Well, she threatened to go buy a new dryer, I took her more seriously. I thought perhaps a thermal protection was the cause. But when I dug into it, I learned that when those trip out, they are permanent (have to be replaced).

I finally noticed loud humming sound the motor made at start-up, when it failed to start turning on one occasion and eventually tripped out the motors thermal protection.

I ordered the new drive motor form PartSelect.com.

Replacing the motor was fairly easy if you like to take stuff apart. One thing that I had not anticipated was that the two foam gaskets on the exhaust duct were dry rotted. I went to my local part supplier to get them. They did not have them in stock. :( While I was there, I asked how much the motor was, they wanted $50 more than PartSelect.com :D

I put it back together without the new gaskets, and it runs like new. I ordered the gaskets from PartSelect and will add them when they arrive.

My wife is happy again, she can bust out the laundry in one day; it had been taking here all weekend.

I learned to take her at her word.

Well, she threatened to go buy a new dryer, I took her more seriously. I thought perhaps a thermal protection was the cause. But when I dug into it, I learned that when those trip out, they are permanent (have to be replaced).

I finally noticed loud humming sound the motor made at start-up, when it failed to start turning on one occasion and eventually tripped out the motors thermal protection.

I ordered the new drive motor form PartSelect.com.

Replacing the motor was fairly easy if you like to take stuff apart. One thing that I had not anticipated was that the two foam gaskets on the exhaust duct were dry rotted. I went to my local part supplier to get them. They did not have them in stock. :( While I was there, I asked how much the motor was, they wanted $50 more than PartSelect.com :D

I put it back together without the new gaskets, and it runs like new. I ordered the gaskets from PartSelect and will add them when they arrive.

My wife is happy again, she can bust out the laundry in one day; it had been taking here all weekend.

I learned to take her at her word.

Parts Used:

-

Ernest from Beaumont, TX

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Wrench (Adjustable)

24 of 28 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Leaking siphon break valve

1. Unplug power to the washer.

2. Remove 2 screws from bottom front panel on either side. Panel then rotates out and unhooks at the top. Remove front panel

3. Remove bolts from underneath the top front on both sides using a socket.

4. Rotate the top upward to provide space to see and work.

5. From the back of the washer, remove 4 bolts using a socket around the drain tube at the upper left.

6. From the front, the siphon valve can be removed from the inside upper right.

7. From the front, unscrew the clamp holding the drain hose on the water pump housing at the bottom right front and remove the hose. Be prepared for water to drain from the hose. Remove hose and siphon valve together and discard.

8. Install new hose on new siphon valve and screw new clamp tight. Make sure the rubber ring is inserted properly on the new valve (See old valve for reference)

9. Holding the siphon valve in place, use a socket and re-attach the 4 bolts around the drain tube at the back of the washer.

10. From the front, insert the opposite end of the new hose to the water pump at the lower right front and screw the circle clamp tight. Note: Re-use existing clamp.

11. Rotate the top back down into normal position.

12. Plug the power back in and run a short cycle and watch for leaks.

13. If no leaks, re-attach bolts for the top with a socket.

14. Re-attach front panel with 2 screws. Done.

2. Remove 2 screws from bottom front panel on either side. Panel then rotates out and unhooks at the top. Remove front panel

3. Remove bolts from underneath the top front on both sides using a socket.

4. Rotate the top upward to provide space to see and work.

5. From the back of the washer, remove 4 bolts using a socket around the drain tube at the upper left.

6. From the front, the siphon valve can be removed from the inside upper right.

7. From the front, unscrew the clamp holding the drain hose on the water pump housing at the bottom right front and remove the hose. Be prepared for water to drain from the hose. Remove hose and siphon valve together and discard.

8. Install new hose on new siphon valve and screw new clamp tight. Make sure the rubber ring is inserted properly on the new valve (See old valve for reference)

9. Holding the siphon valve in place, use a socket and re-attach the 4 bolts around the drain tube at the back of the washer.

10. From the front, insert the opposite end of the new hose to the water pump at the lower right front and screw the circle clamp tight. Note: Re-use existing clamp.

11. Rotate the top back down into normal position.

12. Plug the power back in and run a short cycle and watch for leaks.

13. If no leaks, re-attach bolts for the top with a socket.

14. Re-attach front panel with 2 screws. Done.

Parts Used:

-

Steven from Indianapolis, IN

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set

24 of 29 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

washer wouldn't let the water spin out!

I was told that it might be a clog in the tube.. we check the tubes that wasn't it Then I Google it and was told it might be the drain pump. I was just glad that Part Select had what I need because my machine is over 20 years old. We change the pump and now I hope I get at least another 20 years out of my machine. I will always use part select to get my parts. Thanks

Parts Used:

-

SHARON from DETROIT, MI

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Socket set

22 of 23 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Push start and the motor would hum.

**** Remove power cord from the wall****

As said earlier, you will need to lift the top. Drop the two screws holding the lint shoot and pop the top by sliding a screw driver into the corner on the front. Lif tthe top and rest against the wall behid the unit. remove the two (4 total) screws at the top and bottom of the front door assembly.

Place sometin under the front portion of the drum. At this point you'll see the need to clean everything! :) Slide the belt off and around the drum, (take note of the routing it takes.) Remove the drum by gently pulling it towards you. Set it aside. Clean more. :) (It is nice to have a vacuum handy.) At this point you really need to get to the rear of the system. So I tipped the top back down, and spun it around. Removed the rear panel and cleaned some more. (15 years of a lot of lint in there!) Then you'll need to remove the rear cover on the left side, covering the blower impeller. Get read for a whole lot of debris. Vacuum again. So now you have the motor exposed in the front and rear. You need to remove the impeller by turning that clockwise to loosen it. The trick is holding the shaft in place from the front at the same time. I used an old rag and wedged it into the impeller edges and worked it around until it jamed up. Once the rag was wedged pretty good, I went back to the front spun the shaft. Then you can remove the impeller by hand. Vacuum more. You may get by without having to remove the lint shoot completely, but I did just to clean it up more. I did have to remove two screws in the upper corner near the top of the lint shoot. (Basically the hold the back in place.) I took a few notes at this point about the wiring harness. Used a heavier screw driver (standard), You can push down on the clips that hold the old motor in place. Then work it out the front. Clean more. The new motor is not an exact replacement slightly differnt but the instructions with it were ok. Follow them for the correct wiring. You will need to remove one wire and cut and recrimp a spade lug or two. I used ty-wraps to secure the lines back in place. Look closely at the diagrams and make sure you set the motor down in the same direction the instructions say, if you twist it slightly it will sorta lock in place where it needs to be. Re-install the hold down clips to the front and rear of the motor. Clean up your impeller, and reinstall it too. Then basically reassemble the dryer...tracing your steps backwards. This isn't really difficult, it just takes time and as you can see, you will/should clean as you go !

As said earlier, you will need to lift the top. Drop the two screws holding the lint shoot and pop the top by sliding a screw driver into the corner on the front. Lif tthe top and rest against the wall behid the unit. remove the two (4 total) screws at the top and bottom of the front door assembly.

Place sometin under the front portion of the drum. At this point you'll see the need to clean everything! :) Slide the belt off and around the drum, (take note of the routing it takes.) Remove the drum by gently pulling it towards you. Set it aside. Clean more. :) (It is nice to have a vacuum handy.) At this point you really need to get to the rear of the system. So I tipped the top back down, and spun it around. Removed the rear panel and cleaned some more. (15 years of a lot of lint in there!) Then you'll need to remove the rear cover on the left side, covering the blower impeller. Get read for a whole lot of debris. Vacuum again. So now you have the motor exposed in the front and rear. You need to remove the impeller by turning that clockwise to loosen it. The trick is holding the shaft in place from the front at the same time. I used an old rag and wedged it into the impeller edges and worked it around until it jamed up. Once the rag was wedged pretty good, I went back to the front spun the shaft. Then you can remove the impeller by hand. Vacuum more. You may get by without having to remove the lint shoot completely, but I did just to clean it up more. I did have to remove two screws in the upper corner near the top of the lint shoot. (Basically the hold the back in place.) I took a few notes at this point about the wiring harness. Used a heavier screw driver (standard), You can push down on the clips that hold the old motor in place. Then work it out the front. Clean more. The new motor is not an exact replacement slightly differnt but the instructions with it were ok. Follow them for the correct wiring. You will need to remove one wire and cut and recrimp a spade lug or two. I used ty-wraps to secure the lines back in place. Look closely at the diagrams and make sure you set the motor down in the same direction the instructions say, if you twist it slightly it will sorta lock in place where it needs to be. Re-install the hold down clips to the front and rear of the motor. Clean up your impeller, and reinstall it too. Then basically reassemble the dryer...tracing your steps backwards. This isn't really difficult, it just takes time and as you can see, you will/should clean as you go !

Parts Used:

-

Doug from Manitowoc, WI

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers, Socket set, Wrench (Adjustable)

22 of 26 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Rattling sound.

Turned off circuit breaker. Removed two screws at base of front panel with stubby Phillips-head screwdriver. Swung panel up about 30-degrees, and removed panel, disconnecting red and yellow wire to door switch. Removed four sheet metal screws and took off large drum support bracket. Checked drum support rollers and shafts. They were fine. Reset circuit breaker and turned on dryer. Rattling noise still present.

Removed six small screws holding blower fan assembly. Shaft receiver on squirrel cage fan was worn completely round (it should fit onto a half-round shaft). Ordered new blower fan from PartSelect.com. Replaced tonight, and it works beautifully. This dryer is 29-years old. All it's ever needed in the 10-years I've owned it is a belt replacement and this repair. Long live the 1970s Maytags, and good parts suppliers like this one.

Removed six small screws holding blower fan assembly. Shaft receiver on squirrel cage fan was worn completely round (it should fit onto a half-round shaft). Ordered new blower fan from PartSelect.com. Replaced tonight, and it works beautifully. This dryer is 29-years old. All it's ever needed in the 10-years I've owned it is a belt replacement and this repair. Long live the 1970s Maytags, and good parts suppliers like this one.

Parts Used:

-

Laurence from Leesburg, VA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers, Socket set

21 of 24 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer was making awful noise during use

Removed the screws and took the door off then took the front panel off and popped up the top. Then pulled the drum out. Took snap ring pliers and removed rollers and replaced with new rollers then vacuumed all lint from machine and reversed operation to put everything back together. Operation was a total success!

Parts Used:

-

Pam from Aberdeen, WA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers

20 of 22 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer had burning Smell - Start/Run windings problem

** Your best bet is to use a digital camera to take pictures of the various stages as you take apart the dryer - especially the wiring. And, use masking tape to label all the wires.

** I removed the Blower Housing which made the process much easier.

** Find a friend with or buy the snap ring pliers

** Big Secret not mentioned anywhere - the Motor Support (diag. #20) can be removed ! Hence - the entire Motor assembly can be taken out to remove those irascible Motor Clips.

** For the Green ground wire going from the dryer frame to the motor, you need to take the screw from the old motor and use it to screw into a hole marked with a black "slash" on the new motor.

** After 3 days of WD 40 and an allen wrench, I could not remove the Motor Pully from the old motor, so I would buy one if I were you.

** Hardest Parts - Removing the Motor Clips, reattaching the idler spring!, having another person hold the drum while I installed the Belt and reattached the front drum frame thingy, and deciphering my wiring schematic and reassembly diagrams ! That is why a digital camera is so helpful.

** The process is really very easy if you use the suggestions above and read the others.

** Find the "Model Diagram" on the PartSelect website - an excellent resource !!

** A twenty+ year old Maytag - up and running again !! Many thanks to others who shared their story.

** I removed the Blower Housing which made the process much easier.

** Find a friend with or buy the snap ring pliers

** Big Secret not mentioned anywhere - the Motor Support (diag. #20) can be removed ! Hence - the entire Motor assembly can be taken out to remove those irascible Motor Clips.

** For the Green ground wire going from the dryer frame to the motor, you need to take the screw from the old motor and use it to screw into a hole marked with a black "slash" on the new motor.

** After 3 days of WD 40 and an allen wrench, I could not remove the Motor Pully from the old motor, so I would buy one if I were you.

** Hardest Parts - Removing the Motor Clips, reattaching the idler spring!, having another person hold the drum while I installed the Belt and reattached the front drum frame thingy, and deciphering my wiring schematic and reassembly diagrams ! That is why a digital camera is so helpful.

** The process is really very easy if you use the suggestions above and read the others.

** Find the "Model Diagram" on the PartSelect website - an excellent resource !!

** A twenty+ year old Maytag - up and running again !! Many thanks to others who shared their story.

Parts Used:

-

Thomas from Raleigh, NC

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Wrench set

19 of 21 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Agitator Not Woking

Unplugged power cord then disconnected the water supply and drain hose. Removed 2 screws and took the front panel off. Laid washer on it's side and posistioned the transmission with the cover facing upward. Removed the hex head screws then used a razor knife and a putty knife to remove the silicone sealant. Found that the agitator shaft spring had broken and fallen into the housing jamming the gears that's used in agitation. Removed the oil and all broken pieces of the spring. Installed new shaft spring, replaced the oil then applied sealant to the cover and screwed the cover back down. Let the washer stay in the same posistion for about 18 hours to let sealant dry completely. Then I sat the washer back on it's feet and removed 2 screws that holds the top lid in place. This allowed me access to the tub cover where the injector t is located. Installed the injector t along with the injector tube seal. Connected the hose and hose clamp. Then I put the lid back down and secured with the screws. Connected the water supply and drain hose then the power and selected a wash time and observed the operation. Everything worked ok so I put the front cover back on. Note: I had used the injector t from this washer to fix another washer that an appliance dealer had given me to use for parts to repair the one just described above. That was the only thing that was wrong with it. It was used for about a year and a half and it developed a problem in the spin cycle. Appears to be a brake problem. I intend to repair it as well.

Parts Used:

-

Richard from Alexander City, AL

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set

20 of 24 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer would fill up, wash, then stop

I deduced the lid switch was the problem.

I removed the two screws holding the control panel on. Pulled the control panel back.

Disconnected the ground wire of the lid switch.

removed the two top clamps that hold the panel to the top of the machine.

Pulled back the casing (outside of the washer) and placed it on it's side on the floor. Here I could reach the switch. Removed old, installed new and reversed the process.

The part that gave me the biggest problem was setting the casing back on to the frame. You have to slide the front part in at the bottome, then lean back the rest of it.

I removed the two screws holding the control panel on. Pulled the control panel back.

Disconnected the ground wire of the lid switch.

removed the two top clamps that hold the panel to the top of the machine.

Pulled back the casing (outside of the washer) and placed it on it's side on the floor. Here I could reach the switch. Removed old, installed new and reversed the process.

The part that gave me the biggest problem was setting the casing back on to the frame. You have to slide the front part in at the bottome, then lean back the rest of it.

Parts Used:

-

Glen from Plano, TX

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

22 of 30 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer leaking badly and making loud noise on spin

Determined the tub seal was bad and ordered the seal and tub bearing. Removed the front cover with two phillips screws and unbolted the top to lift back. Removed the agitator with 1/4" setscrew on side and lifted out. Using punch and hammer, broke the inner tub nut loose (clockwise is off). Lifted out the inner tub, unscrewed springs from the bottom and removed; then removed the bearing with a little prying (had to raise the tub slightly and tap the center splined shaft to push out) and lifted out the outer tub. Outer tub had few rust spots about to penetrate, so sanded off rust, primed with etching auto primer and sprayed enamel topcoat to prevent further corrosion. Reassembled in the same order.

When done, there was still a loud noise on the spin cycle, so obtained a spin bearing and brake assembly (need to replace both most always). Tilted the machine on its back and removed the pulley, then put a special wrench on the brake assembly and broke loose (counterclockwise) with a 3 foot extension after placing a 2x4 section in the tub between wall and one of the bases for the spring arms (to keep the tub from turning). When the brake came off it was full of water and corroded from the leaking tub bearing previously replaced. Reassembled in reverse order and replaced two belts on the bottom for good measure. Works perfectly now and is very quiet.

In my estimation, the repair should have included both the tub bearing/seal and the spin bearing/brake assy from the outset. Could have used a chain visegrip wrench instead of special tool to remove the brake assy - whatever is available. The tool costs a lot and will never be used again.

When done, there was still a loud noise on the spin cycle, so obtained a spin bearing and brake assembly (need to replace both most always). Tilted the machine on its back and removed the pulley, then put a special wrench on the brake assembly and broke loose (counterclockwise) with a 3 foot extension after placing a 2x4 section in the tub between wall and one of the bases for the spring arms (to keep the tub from turning). When the brake came off it was full of water and corroded from the leaking tub bearing previously replaced. Reassembled in reverse order and replaced two belts on the bottom for good measure. Works perfectly now and is very quiet.

In my estimation, the repair should have included both the tub bearing/seal and the spin bearing/brake assy from the outset. Could have used a chain visegrip wrench instead of special tool to remove the brake assy - whatever is available. The tool costs a lot and will never be used again.

Parts Used:

-

Barry from Brooklyn, NY

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Screw drivers, Socket set, Wrench set

19 of 22 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Stripped leveler screw making impossible to level my washer

Put blocks under the washer where the leveling leg was needed and screwed the part into the washer. Then it was just a matter of moving the washer into place and leveling. Pretty easy.

Parts Used:

-

Rebecca from Wylie, TX

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Wrench set

21 of 28 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

lint filter shredded after 24 years

pulled out filter measured it looked on internet found this site ordered it threedays later BINGO new filter thank you!

Parts Used:

-

barbara from merrick, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

18 of 20 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

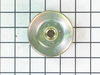

no water drain

removed old pully, put new one on with hex driver, removed belts, put new belts on and finished.

Parts Used:

-

Franz from Lakeland, FL

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

20 of 26 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

My washer stopped draining

My washer filled up and wouldn't drain at all.

I tried checking the fuses, then read that the belt could be broken or worn. I checked under the hood and the belt was broken right in two. I drained the washer manually then ordered the new belt.

I was able to replace the belt in no time with no effort at all.

I tried checking the fuses, then read that the belt could be broken or worn. I checked under the hood and the belt was broken right in two. I drained the washer manually then ordered the new belt.

I was able to replace the belt in no time with no effort at all.

Parts Used:

-

Jenna from St. Louis, MO

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

24 of 39 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!