FLSE72GCS4 Frigidaire Washer Dryer Combo - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Loud Squeek while the dryer is running.

1. After checking the Parts Select website for some useful information I unplugged the dryer.

2. I popped the two clips holding the top down and lifted the top up and out of the way.

3. I used the 8mm socket and screwdiver combo to remove the two screws holding the front of the dryer on. These screws are so close to the sides of the dryer that you need something very thin to seat the socket, it is so thin a small rachet would not fit.

4. Once the to screws are free to forget to unhook the two wires that lead to the automatic cutoff switch on the right. Label them and move them out of the way.

5. The front of the dryer should pivot forward and come right off. Don't forget about the two clips at the bottom, they are not really attached to anything and can be easy to lose.

6. Get your screwdriver and dive into the drum, on the back should be three screws, take those out.

7. Spin the dryer around and take off the vent cover in the lower left corner of the back of the dryer, watch out the socket is a smaller size.

8. Once inside there is an idler pulley like on the back of a ten speed bike, pull the tension out of it and take the drive belt off the pulleys.

9. The drum should be able to be pulled out the front of the dryer, set aside with the door. The screws on my dryer were so tight I had to use a hammer drill to remove them.

10. This is were I got stuck, no one mentioned how to get the bearing plate off, as if everyone would just know. You must lift up on the bearing plate and once it moves up then you can pull it out.

11. Use the 8mm socket to unscrew the old plastic bearing guide. The small metal clip on the back of the dryer will fall off with the grounding ball bearing.

12. With brum bearing kit in hand start off by putting as much high temp lubricant as you can into the bottom of the new bearing guide. I also use a little lubricant like glue to hold the new grounding ball bearing in the little hole on the back of the bearing guide.

13. Here is the tricky part you have to screw the bearing guide into the the dryer while simulaneously holding the little metal clip in place on the back of the dryer. I used duct tape to hold the metal clip and once the screws got started I just took the tape off.

14. Now you have to do the impossible, the bearing must be screwed to the drum. So unless you have 7 foot long arms you can't hold the bearing and drive the screws. Another problem is the bearing itself, the holes are not the same size as the original and they are not threaded. I stripped every screw that came with the kit trying to get them through the metal of the bearing.

15. With an unwilling victim holding the bearing steady I finally got a replacement screw to seat through the bearing. Once you get one the rest are easier.

16. You are ready to reassemble, after vacuuming everything ou, pick up the drum making sure the belt is around the drum about where it was when you took it off. Push the drum through the front of the dryer all the way to the back, aim a little high so the bearing can move down and seat in the bearing guide.

17. Tuck the clips on the front panel of the dryer into the bottom front edge of the dryer and the whole front should pivot up, when you get it almost closed you will have to lift the drum and set it on the front bearing in the door.

18. While holding the front of the dryer on you have to reach inside and get the 8mm screw started on the left or right, if you let go the front of the dryer will pop off and you have to start over with the pivot. Now is a good time to have a magnet on a stick so when you drop the screw or screw driver you don't have to take the front off to retrieve your tools.

19. Once the front is on reconnect the two wires to the switch in the front of the dryer. Remember the ones you were supposed to have labeled earlier.

20. Close the top of the dryer and spin the dryer around so you can reach inside the vent door and pull the tension pulley over and reseat the drive belt. Rem

2. I popped the two clips holding the top down and lifted the top up and out of the way.

3. I used the 8mm socket and screwdiver combo to remove the two screws holding the front of the dryer on. These screws are so close to the sides of the dryer that you need something very thin to seat the socket, it is so thin a small rachet would not fit.

4. Once the to screws are free to forget to unhook the two wires that lead to the automatic cutoff switch on the right. Label them and move them out of the way.

5. The front of the dryer should pivot forward and come right off. Don't forget about the two clips at the bottom, they are not really attached to anything and can be easy to lose.

6. Get your screwdriver and dive into the drum, on the back should be three screws, take those out.

7. Spin the dryer around and take off the vent cover in the lower left corner of the back of the dryer, watch out the socket is a smaller size.

8. Once inside there is an idler pulley like on the back of a ten speed bike, pull the tension out of it and take the drive belt off the pulleys.

9. The drum should be able to be pulled out the front of the dryer, set aside with the door. The screws on my dryer were so tight I had to use a hammer drill to remove them.

10. This is were I got stuck, no one mentioned how to get the bearing plate off, as if everyone would just know. You must lift up on the bearing plate and once it moves up then you can pull it out.

11. Use the 8mm socket to unscrew the old plastic bearing guide. The small metal clip on the back of the dryer will fall off with the grounding ball bearing.

12. With brum bearing kit in hand start off by putting as much high temp lubricant as you can into the bottom of the new bearing guide. I also use a little lubricant like glue to hold the new grounding ball bearing in the little hole on the back of the bearing guide.

13. Here is the tricky part you have to screw the bearing guide into the the dryer while simulaneously holding the little metal clip in place on the back of the dryer. I used duct tape to hold the metal clip and once the screws got started I just took the tape off.

14. Now you have to do the impossible, the bearing must be screwed to the drum. So unless you have 7 foot long arms you can't hold the bearing and drive the screws. Another problem is the bearing itself, the holes are not the same size as the original and they are not threaded. I stripped every screw that came with the kit trying to get them through the metal of the bearing.

15. With an unwilling victim holding the bearing steady I finally got a replacement screw to seat through the bearing. Once you get one the rest are easier.

16. You are ready to reassemble, after vacuuming everything ou, pick up the drum making sure the belt is around the drum about where it was when you took it off. Push the drum through the front of the dryer all the way to the back, aim a little high so the bearing can move down and seat in the bearing guide.

17. Tuck the clips on the front panel of the dryer into the bottom front edge of the dryer and the whole front should pivot up, when you get it almost closed you will have to lift the drum and set it on the front bearing in the door.

18. While holding the front of the dryer on you have to reach inside and get the 8mm screw started on the left or right, if you let go the front of the dryer will pop off and you have to start over with the pivot. Now is a good time to have a magnet on a stick so when you drop the screw or screw driver you don't have to take the front off to retrieve your tools.

19. Once the front is on reconnect the two wires to the switch in the front of the dryer. Remember the ones you were supposed to have labeled earlier.

20. Close the top of the dryer and spin the dryer around so you can reach inside the vent door and pull the tension pulley over and reseat the drive belt. Rem

Parts Used:

-

Miles from LaPorte, IN

-

Difficulty Level:Very Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Screw drivers, Socket set, Wrench set

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Loud Squeaking c/c unlevel. Led to shaft breaking

Took off all controls and panel. Removed the top. Pulled out the drum. Unscrewed shaft and bearing holder. Replaced all parts and started it back up.

--The parts were shipped timely,

--The parts were shipped timely,

Parts Used:

-

Chad from Reisterstown, MD

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Worn front drum slides

The disassembly was very easy and it appeared that this would be a very quick repair. But the removal of the old felt was difficult and once it was removed it took a lot of effort to remove the bits still stuck on. The tool of choice to remove the stuck on felt was a small torch. After that use a coarse sand paper to remove the remnants. Glue on the new felt and reinstall the front panel.

Parts Used:

-

David from Plymouth, ME

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

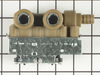

Remote drain pump leaking

First, I unplugged the washer then removed the front panel to the washing machine, then the pump cover, then the two hoses connected to the pump, draining them into a small bowl. I removed the ground wire and electrical connections.

Then I removed the two bolts holding down the pump and removed it. I had to pivot the hose connections on the pump to match the old one. Once I did this, I removed the hold-down bracket from the old pump and installed it on the replacement pump.

Getting the hoses clamped back on the new pump was a challenge, and I finally used an automotive clamp on the rear hose. Once the hoses were connected, I bolted the pump back in, reconnected the power and ground connections and replaced the cover.

Overall, it was a fairly straightforward installation and the only challenging part was the hose clamps.

Then I removed the two bolts holding down the pump and removed it. I had to pivot the hose connections on the pump to match the old one. Once I did this, I removed the hold-down bracket from the old pump and installed it on the replacement pump.

Getting the hoses clamped back on the new pump was a challenge, and I finally used an automotive clamp on the rear hose. Once the hoses were connected, I bolted the pump back in, reconnected the power and ground connections and replaced the cover.

Overall, it was a fairly straightforward installation and the only challenging part was the hose clamps.

Parts Used:

-

Steven from Gilbert, AZ

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set, Wrench (Adjustable)

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The drum was squeaking and running slow

Removed drum replaced bearing with kit, replaced both front drum seals and drive belt. The only problem was when replacing the rear drum ball the three screw holes were poorly tapped and took several tries to get them in. The manufacturers could easily fix this problem. They could provide self tapping hex head screws instead of the Phillips head screws. Everything else went very smoothly.

Parts Used:

-

Terry from TENINO, WA

-

Difficulty Level:Really Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Squeaky drum until drum would not turn.

Watched on-line video, then applied those steps.

1. Pop the front of the deck loose using putty knife to depress clips;

2. Disconnect wires from light and door switch;

(Before I disconnected wires from door switch and light, I made wiring sketches to make sure I reconnected in original manner.)

3. Remove lint filter mount screws and mount from bottom of door opening;

4. Cut drum belt with wire-cutters and removed it;

5. Remove drum support clip from top center of front panel;

6. Remove (1) screw from each side of dryer body that hold front to sidewalls, removed front panel;

7. Remove drum by lifting the rear out of the bearing, then moving it forward through the machine front;

[While I had the dryer disassembled, I thoroughly cleaned it of lint, dirt & metal filings. The metal filings were from the worn ball hitch and drum support bearing cup. I spent as much time cleaning it out as I did working on it.]

8. Stand drum on gallon paint bucket while removing ball hitch (Use a #2 drywall phillips apex to obtain sufficient seating & torque to remove and reinstall ball hitch screws at rear of drum.);

9. Have a second person hold the new ball hitch in position while starting screws, if necessary;

10. Use nut driver w/5/16" socket to remove bearing retainer & ground ball clip;

11. Install new bearing into retainer clip, insert attachment screws through the holes in both, stick grounding ball in depression on back of bearing as screws are fed through back panel;

12. Hold ground ball clip in place to start one screw, then the other & tighten with nut driver;

13. Start drum belt on motor shaft and position against tensioner pulley;

14. Feed drum through front of machine and loop belt over rear of drum;

15. Slide belt forward on drum as drum moves to rear to keep it aligned with position of tension pulley;

16. Lift rear of drum to place ball hitch on top of bearing, then press down to seat it into bearing;

17. Turn drum to ensure belt alignment, then re-accomplish steps 6 thru 1.

1. Pop the front of the deck loose using putty knife to depress clips;

2. Disconnect wires from light and door switch;

(Before I disconnected wires from door switch and light, I made wiring sketches to make sure I reconnected in original manner.)

3. Remove lint filter mount screws and mount from bottom of door opening;

4. Cut drum belt with wire-cutters and removed it;

5. Remove drum support clip from top center of front panel;

6. Remove (1) screw from each side of dryer body that hold front to sidewalls, removed front panel;

7. Remove drum by lifting the rear out of the bearing, then moving it forward through the machine front;

[While I had the dryer disassembled, I thoroughly cleaned it of lint, dirt & metal filings. The metal filings were from the worn ball hitch and drum support bearing cup. I spent as much time cleaning it out as I did working on it.]

8. Stand drum on gallon paint bucket while removing ball hitch (Use a #2 drywall phillips apex to obtain sufficient seating & torque to remove and reinstall ball hitch screws at rear of drum.);

9. Have a second person hold the new ball hitch in position while starting screws, if necessary;

10. Use nut driver w/5/16" socket to remove bearing retainer & ground ball clip;

11. Install new bearing into retainer clip, insert attachment screws through the holes in both, stick grounding ball in depression on back of bearing as screws are fed through back panel;

12. Hold ground ball clip in place to start one screw, then the other & tighten with nut driver;

13. Start drum belt on motor shaft and position against tensioner pulley;

14. Feed drum through front of machine and loop belt over rear of drum;

15. Slide belt forward on drum as drum moves to rear to keep it aligned with position of tension pulley;

16. Lift rear of drum to place ball hitch on top of bearing, then press down to seat it into bearing;

17. Turn drum to ensure belt alignment, then re-accomplish steps 6 thru 1.

Parts Used:

-

Doug from ODESSA, TX

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer heater broken

Removed top cover.

Lowered control assembly.

Removed front door assembly.

Removed drum.

Removed heater assembly.

Removed support bearing and bracket using existing bonding ball.

Re-assembled in reverse order.

Lowered control assembly.

Removed front door assembly.

Removed drum.

Removed heater assembly.

Removed support bearing and bracket using existing bonding ball.

Re-assembled in reverse order.

Parts Used:

-

Johnny from PINEBLUFF, NC

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Leaking through the main tub seal

-Remove front panel - 2 screws

-Remove the top panel - 2 screws

-Disconnect the lid switch from the top panel - 2 screws

-Remove the agitator cap - unscrew

-Remove the agitator - This was a bit difficult and required a lot of jiggling but it eventually came off

-Remove the inner drum - 5 bolts at the bottom

-Remove the drum mount - 2 bolts and then it got really difficult. A lot of penetrating blaster, wire brushing, jiggling, and some strategically placed hammer taps (don't damage the threads.

-Remove the seal

-Clean up the inner and outer seal seating surfaces

-Rinse and repeat in reverse (pun intended)

-Remove the top panel - 2 screws

-Disconnect the lid switch from the top panel - 2 screws

-Remove the agitator cap - unscrew

-Remove the agitator - This was a bit difficult and required a lot of jiggling but it eventually came off

-Remove the inner drum - 5 bolts at the bottom

-Remove the drum mount - 2 bolts and then it got really difficult. A lot of penetrating blaster, wire brushing, jiggling, and some strategically placed hammer taps (don't damage the threads.

-Remove the seal

-Clean up the inner and outer seal seating surfaces

-Rinse and repeat in reverse (pun intended)

Parts Used:

-

Rob from DACULA, GA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Screw drivers, Socket set

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

no filter

-

Luis from La Jolla, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

4 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Leveling Leg Broken

The leveling legs on my Frigidaire stackable washer & dryer were broken. They are made of plastic and while moving the unit one of the legs had broke off. I ordered two replacements from PartSelect and received them within a few days. The old legs were removed by screwing them out and then the new ones were installed. Pretty easy installation for DIY. The new legs work great.

Parts Used:

-

Brian from Rochester, NH

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Wrench (Adjustable)

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

over filling

no problemO top loader. open top, disco two electrical plugs and a small hose, then remove two screws that hold valve in place and remove. Re install in reverse order. Thanks for your support Eliot in Alaska!

Parts Used:

-

eliot from fairbanks, AK

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

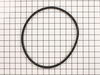

Washer tub was not spinning

Smelled burning rubber, checked belt. Belt was cracked and worn out. Easy repair. Removed front of the machine held together with two screws at the bottom of the unit. Removed top cover of machine (the part with the lid). It just pops off. Pushed tensioner wheel in and took off old belt. Putting new belt on was super easy. Working like a champ now. $20 total with shipping. Not too bad to save a washing machine.

Parts Used:

-

josef from Nashville, TN

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Loud Squealing

Remove top panel with large flat screwdriver and 2 screws in back.Remove bottom panel with 2 screws.Release belt tensioner and remove belt.Remove 3 screws in center of drum inside.Remove drum. Remove rear bearing by pulling up on assembly.Replace all parts in reverse order.

Parts Used:

-

William from Hudson Falls, NY

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Drive Belt Was Noisy-Slipping

I just popped up the top front using a large straight (slotted) screw driver, then removed the 2 screws at the bottom front, then the whole front panel popped down about a half inch to be lifted out of the way. I found the old drive belt way down under the motor (still attached as normal), very near the floor and removed the worn out belt by hand, and replaced it with the new belt by hand also. The spring loaded belt tightener- idler wheel makes this a very simple process to accomplish. Then, I replaced the front panel-- all done. Works like new.

Parts Used:

-

Steve from Carrollton, TX

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

3 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Glides and felt worn out. Rust spots on clothing and clothes with strings getting caught.

First, I read the other posts and got a good idea as to how to do it. I needed to replace the upper felt and guides but decided to go ahead and replace the lower felt and the bearing holder as well. If I had been thinking I would have replaced the belt at the same time but, oh well.

Disconnect the electric plug from the wall.

Pop the top using a medium sized flat head screwdriver.

Disconnect the wiring harness at right front of the unit.

Remove the two screws near the top of the front panel and squeez the retaining clips. You may need a pair of pliers for this but be gentle.

Pull straight up on the front panel to remove it.

To get to the bearing holder, remove the drum by first removing the access panel located at the rear of the dryer and removing the belt from the springloaded plastic pulley. With no tension on the belt simply pull up on the drum while also pulling slightly forward. The drum will pop right out but you will have to apply some pressure. There is no need to remove the three screws at the back of the drum on the inside.

Once the drum is out, remove the two screws holding the bearing holder and remove the assembly being careful not to lose the single ball bearing at the rear of the assembly. Pay attention as to how the assembly goes together.

Scrape off the old felt and glue. Like everyone else, I used a chisle and some GOOP. The old felt came right off with little effort and the GOOP cleaned off the old glue with not too much effort.

Apply the glue that comes with the felt glides according to the instructions on the tube. There's plenty to do both upper and lower felt in that tube. I used some spring clamps to firmly set the upper felt. The glue sets in just a few minutes. The lower felt has a bevelled edge that goes toward the door and fits into a groove on the panel. Once the glue is set you you are ready to put it back together. Like everyone else, I took the time to vacuum out the interior of the dryer and collect the coins and buttons that had accumulated. I found it very easy to reinstall the bearing holder assembly by myself by working from the side of the dryer. I put a dab of grease on the single ball bearing to hold it in place while I reinstalled the assembly. Put some grease in the bearing holder and reinstall the drum, then the front panel and belt. Put the belt back on the tensioner and take care of the couple of lose end and you're done.

This is a "no big deal" repair that looks worse than it is. It took me about 2.5 hours to complete and I was taking my time and just enjoying the fact that I was doing it myself.

Disconnect the electric plug from the wall.

Pop the top using a medium sized flat head screwdriver.

Disconnect the wiring harness at right front of the unit.

Remove the two screws near the top of the front panel and squeez the retaining clips. You may need a pair of pliers for this but be gentle.

Pull straight up on the front panel to remove it.

To get to the bearing holder, remove the drum by first removing the access panel located at the rear of the dryer and removing the belt from the springloaded plastic pulley. With no tension on the belt simply pull up on the drum while also pulling slightly forward. The drum will pop right out but you will have to apply some pressure. There is no need to remove the three screws at the back of the drum on the inside.

Once the drum is out, remove the two screws holding the bearing holder and remove the assembly being careful not to lose the single ball bearing at the rear of the assembly. Pay attention as to how the assembly goes together.

Scrape off the old felt and glue. Like everyone else, I used a chisle and some GOOP. The old felt came right off with little effort and the GOOP cleaned off the old glue with not too much effort.

Apply the glue that comes with the felt glides according to the instructions on the tube. There's plenty to do both upper and lower felt in that tube. I used some spring clamps to firmly set the upper felt. The glue sets in just a few minutes. The lower felt has a bevelled edge that goes toward the door and fits into a groove on the panel. Once the glue is set you you are ready to put it back together. Like everyone else, I took the time to vacuum out the interior of the dryer and collect the coins and buttons that had accumulated. I found it very easy to reinstall the bearing holder assembly by myself by working from the side of the dryer. I put a dab of grease on the single ball bearing to hold it in place while I reinstalled the assembly. Put some grease in the bearing holder and reinstall the drum, then the front panel and belt. Put the belt back on the tensioner and take care of the couple of lose end and you're done.

This is a "no big deal" repair that looks worse than it is. It took me about 2.5 hours to complete and I was taking my time and just enjoying the fact that I was doing it myself.

Parts Used:

-

Michael from Snellville, GA

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers, Socket set

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!