11088732795 Kenmore Washer Dryer Combo - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Washer wouldn't spin, or agitate

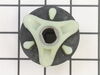

First, I turned the machine on it's side to provide access to the bottom/motor coupling area, then I removed the two motor straps that are connected with bolts to uncouple the motor to the coupling and transmission/pump, I also removed the hoses to the pump, then I separated the motor, then I removed the rest of the pieces of the old coupling, and then installed the new coupling, and put it back together, connected the straps back on the sides of the motor.

Parts Used:

-

Morgan from Yucaipa, CA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Socket set

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washing machine would not agitate

I first tipped the machine on its side, so that the motor and gearbox would be exposed. I disconnected the hoses from the water mump, and removed it. I then removed the motor by unsnapping the retainer clips. the damaged coupling came off very easily. I just pried it off with a screw driver. I installed the new coupling, and put everything back in reverse order. The machine works great now.

Parts Used:

-

Chris from North Wildwood, NJ

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers, Socket set, Wrench set

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Tub/agitator would not turn or spin, loud clicking sound.

1.Remove drain hose from back with pliers, tip washer on back (important for ease of repair)

2. Remove 2 clips holding pump and push aside

3. Remove 2 screws (use a socket wrench) and unclip two clips holding motor. Disconnect electrical plugs and set moter aside.

4. Replace coupler (new redesigned coupler will need to be put on using a hammer and something (suggest a socket) to seat it as it fits on rather tightly compared to old one. Be sure coupler is correctly assembled and aligned while replacing moter.

5. Reverse process to reassembly.

2. Remove 2 clips holding pump and push aside

3. Remove 2 screws (use a socket wrench) and unclip two clips holding motor. Disconnect electrical plugs and set moter aside.

4. Replace coupler (new redesigned coupler will need to be put on using a hammer and something (suggest a socket) to seat it as it fits on rather tightly compared to old one. Be sure coupler is correctly assembled and aligned while replacing moter.

5. Reverse process to reassembly.

Parts Used:

-

Charles from Lake Mary, FL

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Socket set

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

washer wouldn't agitate or spin

I turned off water supply and unhooked water hoses from washer. I then turned washer around and turned over on its front. This exposed the motor and gear box(transmission). I took hex screw out of clip and snapped off of motor. Then took 3 bolts out of gear box so I could pull it to me and pull it off motor, this separated the coupling so I could pry it off the motor and gear box. I then lined coupling ends with both shafts and used a 1" block of wood and hit it with a hammer to drive new coupling ends in place. Line rubber center piece with holes in coupling ends and push motor back in place, then bolt gear box back, replace strap on motor(being sure to put insulating pad under strap). Line up motor to original position, set washer back up, turn around, hook water hoses back(hot line to hot connection and cold to cold connection). Be sure to check operation before turning water back on.

Parts Used:

-

Floyd from Cumberland Gap, TN

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Socket set

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Motor ran, but tub wouldn't rotate.

I had previously replaced the water pump on this washer, so I knew how to go about getting to the part that had failed this time. I disconnected the power and water lines to the washer. On this particular washer model, it has the easiest access to the coupling by laying the washer on its back panel and accessing the parts from underneath.

First take off the water pump by popping off the two clips with a flat head screwdriver. Loosen the hose clamps with a pair of pliers and slide the hoses off of the water pump.

To remove the motor, remove the two screws holding the clamps in place and then pop off the two clamps.

One half of the coupling will be attached to the motor shaft and the other will be attached to the gearbox shaft. Remove both halves - they should easily slide off. Place each new coupling half on the motor and gearbox shafts. They may need a little "coaxing" - I used a large enough socket to fit on the perimeter of the coupling and a slight tap of a hammer.

Install the new rubber center piece on the coupling. Rotate the motor shaft until the coupling halves line up so you can slide it into the other half of the coupling. Re-attach the motor clips (and screws) and water pump. Re-attach water pump hoses, and you should be good to go.

First take off the water pump by popping off the two clips with a flat head screwdriver. Loosen the hose clamps with a pair of pliers and slide the hoses off of the water pump.

To remove the motor, remove the two screws holding the clamps in place and then pop off the two clamps.

One half of the coupling will be attached to the motor shaft and the other will be attached to the gearbox shaft. Remove both halves - they should easily slide off. Place each new coupling half on the motor and gearbox shafts. They may need a little "coaxing" - I used a large enough socket to fit on the perimeter of the coupling and a slight tap of a hammer.

Install the new rubber center piece on the coupling. Rotate the motor shaft until the coupling halves line up so you can slide it into the other half of the coupling. Re-attach the motor clips (and screws) and water pump. Re-attach water pump hoses, and you should be good to go.

Parts Used:

-

Paul from Danville, CA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers, Socket set

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Ill fitting cover

Unplugged power cord and disconnected the water hoses. Removed screws holding timer and switch unplugging wires to safeties to durm cover. Unsnapped clips holding the cover to frame back and then removed the cover tipping it forward. Removed pump by unsnapping the clips holding it to the motor and then removed motor by taking screws out and then unsnapping the clips. Removed broken coupling halves from both motor and transmission. This took maybe 30 minutes. Installed new coupling by driving onto shafts of transmission and motor with hammer and screwdriver used backwards. Attached motor after aligning coupling halves. Screw clips into place and then replaced pump and clips holding it. Turned motor by hand to make sure everything rotated properly. This took maybe 45 minutes. The rest of the time was spent trying to get the cover to line up on the base tabs. Was not able to get this done so ended up getting one side to fit and the other side I used self tapping screws to fasten the cover to the frame. Of course doing this after 2 hours of trying to keep the cover in line with the tabs trying to hook the clips at the top. With the screws holding the cover to the base no problem of getting the clips in place at the top and then mounting the electrial/electronics to the top. Finished by hooking up the hoses and plugging in the power cord and then testing everything out and all work great and noticed less noise coming from the machine than in the past. The cover engineering leaves something to be desired.

Parts Used:

-

Dennis from Lawrenceville, GA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set, Wrench set

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Top of agitator wasn't moving properly

(For those who have a weird sunken plastic cube slot instead of a nut or screw to remove) The dog teeth were worn down. Generally this is an easy repair. It happened once before to me with a Whirlpool and I knew immediately what I needed to do. HOWEVER, when I popped the plastic cap off the top of the agitator (this model doesn't have the fab softener dispenser) what I found was a surprise. It wasn't an 11mm nut, it wasn't a screw, it was an inverted cubed slot made of plastic (not sure what those are called) that looked like it needed a 3/4 - 1 inch socket drive to go into it. I had nothing that would fit in there to get any leverage to loosen it up. Frustrated, I began grabbing everything I could find to shove in there that I thought might grab to no avail. In pure desperation I grabbed my wife's garden shears (the common little hand-held kind that curve at the end) and it was the perfect size to wedge in just enough to grab the corners of the cubed-shape slot. It took just a little force to loosen and I was able to unscrew it by hand after that. Then the repair was just as it normally is. Remove the top piece of the agitator, remove the spring piece and slip the plastic part up to remove the dog teeth. Replace, put back together in reverse order.

Parts Used:

-

Jonathan from Franklin, TN

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Tub Would Not Spin

Unplugged all electrical connectors, removed gear case & motor as one, separated motor from gearcase, replaced coupler, reinstall, was alot easier than it looks, only thing now is it has a clicking noise when spinning, works fine, will wait for something to break and find out what clicking noise is.

Parts Used:

-

ERIC from SAN JOSE, CA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Socket set

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

plastic parts of coupling degraded

unhook washer lay it on it's back and remove the two 1/4" nuts securing the holding straps on the motor. Seperate the motor from transmission and slip in new coupling. Reverse previous steps to reassemble. Note: remove all rubber dust from the motor so that it doesn't smoke when the motor heats up.

Parts Used:

-

Clifton from Dallas, TX

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers, Socket set

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer wouldn't spin or agitate

1st I took the brackets then water pump off. Then I unscrewed the brackets and took off the motor. Under the motor the coupling just slide off.

Parts Used:

-

Alfreda from Hempstead, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washing machine would not spin or agitate

I moved the washing machine to the garage and while it was still on the dolly, I laid it down so that the underside of the machine was acessible. I then proceeded to remove the hoses from the pump and then removed the pump. This gave me acsess to the motor which I removed after removing the clip screws holding the clips on the motor. After removing the clips, the motor then came free allowing me to pry the remaining pieces of the coupling assembly loose from the shaft of the transmission and the motor. Reversing the procedure allowed me to complete the repair. Using a socket to tap the pieces of the coupling onto the shafts of the motor and the transmission made it easy to get them onto the shafts properly. By the way, I think that if the couplings were made of stainless steel rather than a composit plastic I would not have had to do the repair at all. The rubber center piece was not worn at all. I think that was poor engineering on the part of the designers.

Gene Sinclair. Cedar Park Tx.

Gene Sinclair. Cedar Park Tx.

Parts Used:

-

E. from Cedar Park, TX

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The upper agitator would not work.

Pryed off the upper agitator cap, unbolted the agitator, lifted it out, replaced the dogs, and put it back together. A very easy home repair.

Parts Used:

-

Dennis from Cincinnati, OH

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Socket set

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Broken motor coupling

Just remove the covers, remove the electric drive motor. Replace the failed coupling with the improved design parts. Reinstall motor and covers. Tested OK. The new part will outlast the rest of the machine!

Parts Used:

-

Roger from New City, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

washer failed to spin

after draining washer, I put washer on back. I disconnected water pump, then rmoved motor coupling. Confirming the coupler was cracked, I simply removed ,replaced coupler, connected water pump and positioned washer. I thank this site for assisting me with the fix of my washer.

Parts Used:

-

James from Harrington, DE

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Wrench (Adjustable)

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer would not agitate or spin

First I removed the center cover of the tub, then removed the bolt that was underneath it.

I then tipped the washer back far enough that it wouldn't fall forward.

Next I removed the two hoses connected to the motor/gearbox assembly.

I then removed three bolts that hold the gearbox/motor assembly to the bottom of the tub and slid it down.

The next step is to separate the gearbox from the motor. To do this I removed the spring clips that hold the water pump to the motor, and then the spring clips that hold the gearbox to the motor.

The broken coupling between motor and the gearbox was then removed and replaced with the new one.

Next, put every thing back together.

I then tipped the washer back far enough that it wouldn't fall forward.

Next I removed the two hoses connected to the motor/gearbox assembly.

I then removed three bolts that hold the gearbox/motor assembly to the bottom of the tub and slid it down.

The next step is to separate the gearbox from the motor. To do this I removed the spring clips that hold the water pump to the motor, and then the spring clips that hold the gearbox to the motor.

The broken coupling between motor and the gearbox was then removed and replaced with the new one.

Next, put every thing back together.

Parts Used:

-

Scott from Indian Harbour Beach, FL

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers, Socket set

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!