11023014101 Kenmore Washer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

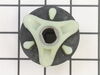

Wash machine, wouldn't spin dry the close. The pump still worked to drain the water.

Unplug power from wall.

Disconnected water lines

Tip Unit on it's side. (Recommend turning so motor is to the top side)

Disconnect Electrical connector and Hoses from the pump and motor.

Disconnect metal straps used to retain the motor to the transmission. (screwdriver to pry)

Remove old coupling pieces from transmission/motor(used a long screw driver, rock back and forth)

used air compressor to clean up electric motor

replace new coupling on motor and transmisison (may need hammer to tap into place)

set rubber bushing on transmission side (transmission shaft should be facing up at this point)

replace electric motor into place, making sure to line up bushing and motor mounts.

replace metal strap connectors between transmission / motor (this can be tricky, as the one in the back is hard to get at.)

replace electrical connectors and hoses

connect washing machine power and water and test

Disconnected water lines

Tip Unit on it's side. (Recommend turning so motor is to the top side)

Disconnect Electrical connector and Hoses from the pump and motor.

Disconnect metal straps used to retain the motor to the transmission. (screwdriver to pry)

Remove old coupling pieces from transmission/motor(used a long screw driver, rock back and forth)

used air compressor to clean up electric motor

replace new coupling on motor and transmisison (may need hammer to tap into place)

set rubber bushing on transmission side (transmission shaft should be facing up at this point)

replace electric motor into place, making sure to line up bushing and motor mounts.

replace metal strap connectors between transmission / motor (this can be tricky, as the one in the back is hard to get at.)

replace electrical connectors and hoses

connect washing machine power and water and test

Parts Used:

-

Matthew from Albany, MN

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers

17 of 27 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

washing machine not draining

Tilt machine on its side,snap off the two retaining straps and remove the pump and sanded the shaft on the electric drive motor to remove rust ,Install new pump and retaining straps and unit now running great.

Parts Used:

-

michael from princeton, TX

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers

10 of 11 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Crossed threaded plastic on old valve was leaking

Removed screws on top of machine to remove the control unit out of the way. Then used large regular screw driver to pry out the two clips that hold the back of the washer tight to the top frame. This allows the back to come away from the machine enough to get the water inlet valve free. Didn't have to remove the bolts at the bottom of the back of the machine (they were pretty rusty) Just removed the single screw holding the water inlet valve in place, slid it down and away from the back cover and could fish it out to the side and disconnect the hose (with plyers) and slide off electrical clips (make a note of which clip goes to which valve.) I removed the part first so I could make sure I was ordering the right one. When the part came (very promptly by the way) it went back together easy. Only question was regarding reinstalling the wires since I didn't mark which way they went. I knew which one went on the Hot and Cold but didn't know if it mattered which clips went on each terminal. Figuring it was AC guessed it didn't matter so put it together the way the connectors seemed to want to lie naturally. Put it together making sure no hoses or wires where pinched or rubbing against sharp edges. Replaced the rubber washers in the hoses and made sure the hose connectors turned freely (they had been rusted a bit and didn't turn on the hose freely and I think this was the start of the cross threading problem) This time the hoses went back on very easily, screwed them hand tight not forcing anything at any time (DIDN"T USE PLIERS!). Tried water and no more leaks. Washer filled faster also, think this was because the screens on the water valve were plugged. I'll have to remember to take the hoses off and make sure the screens are clear every couple years or so. If you are having slow fills, suggest you check this first before tearing in to the machine.

Parts Used:

-

David from Amity, AR

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

11 of 14 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

tub oscillation

placed washer on side and installed new pads

and returned washer upright

and returned washer upright

Parts Used:

-

leonard from phil campbell, AL

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers

12 of 17 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Replaced ring that broke and washer that was bent on the edge.

Took the agitator out and gearbox off unhook wires from motor and take off water pump, replaced the parts and put back together. Pretty easy to fix. However, I still haven't got my problem fixed. Originally the washer wouldn't spin after the rinse. I put on a new coupler and it worked for a few loads, then something smelled hot and started stinkin the house up so I opened the washer lid and smoke rolled out. Turned it off. Took the moter off and checked it and it would barely turn at all. Replaced the motor with a new one. Still wouldn't spin. Put on a new clutch assembly. Still wouldn't spin. Bought a new capacitor thinking that would do it. Still don't SPIN!!! (The ring and washer I replaced was just a casualty, not any of the problem).

Parts Used:

-

Kim from West Liberty, OH

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Wrench (Adjustable)

22 of 47 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washing machine shakes violently during spin cycle

Removed four screws that hold the top control panel to the base and hung over the back panel in order to remove the main wrap-around body of the machine. Took off top plastic ring fastened to side of tub then removed old Balance ring. Installed new balance ring. Unfortunately, this did NOT fix the problem. This was a suggestion from Justanswer.com and failed miserably. Does anybody know how to fix this problem? And it's not the springs or the little plastic shims around the base OR the cross coupling to the motor...

Parts Used:

-

James from Asheville, NC

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

25 of 57 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

My drain hose had cracked and was leaking.

Once I finally found the part I needed, the repair was very simple and took only a few minutes. Thanks to the very helpful operator to walk me through the diagram to find the corresponding number for the part. I really appreciate your help!

Parts Used:

-

Miguel from San rafael, CA

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Wrench (Adjustable)

10 of 12 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer tub off balance and noisy

The repair was fairly simple and while it made the spin operation quieter and and a bit more stable, it still gets out of balance. Disconnected power, shutoff supply lines and disconnected them from the unit.

Laid washer on its front and replaced the two more visible springs fairly easily from underneath using a little leverage with a 2 x 4 to take any residual tension off the springs.

Then I turned the washer over on its back (gently and with a little support (board or old thick towel) so the weight of the unit didn't rest entirely on the water intake connectors

Again, lifted the tub with 2 x 4 and disconnected the power and control connector to the motor to make a little more room to get to the spring.

If you do this, be sure to re-connect that connector before you put the washer back and test, otherwise it will fill and then sit.... I had to siphon the tank out, disconnect everything, flip it over and re-connect that power connector!! After that the unit ran better than before, especially on the spin cycle. Over all this washer is 15 years old and worn a bit so we are still careful not to overload it and balance the loading as much as possible. Large bedspreads and king size sheets or mattress covers will always spin out of balance but for 90% of regular washing it was an improvement.

Laid washer on its front and replaced the two more visible springs fairly easily from underneath using a little leverage with a 2 x 4 to take any residual tension off the springs.

Then I turned the washer over on its back (gently and with a little support (board or old thick towel) so the weight of the unit didn't rest entirely on the water intake connectors

Again, lifted the tub with 2 x 4 and disconnected the power and control connector to the motor to make a little more room to get to the spring.

If you do this, be sure to re-connect that connector before you put the washer back and test, otherwise it will fill and then sit.... I had to siphon the tank out, disconnect everything, flip it over and re-connect that power connector!! After that the unit ran better than before, especially on the spin cycle. Over all this washer is 15 years old and worn a bit so we are still careful not to overload it and balance the loading as much as possible. Large bedspreads and king size sheets or mattress covers will always spin out of balance but for 90% of regular washing it was an improvement.

Parts Used:

-

Gregory from Kent, OH

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers

9 of 10 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer basket off-center and wobbling during spin cycle

Remove the washer case/enclosure to expose all the internal parts. Lie on the floor and with pliers and a strong arm. Remove and replace each spring one at a time. Pretty straightforward.

Parts Used:

-

Craig from Woodland Hills, UT

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

8 of 8 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

there was a hole in the original drain hose

First, I read the previous repair stories, so I knew what step to do first. So, first I took the hose off of the drain, then I removed it from the washer. And as the previous repair story stated, some water came out and I had a towel ready to catch the water that was in the hose. I threaded the clamp onto the new hose, pushed the new hose onto the washer, used the pliers to open the clamp to better clamp the hose onto the washer. Then, placed the drain hose into the drain pipe and it was done! Thanks for such a great site!

Parts Used:

-

Kathy from Pittsburgh, PA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers

10 of 14 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Broken water inlet syphon combined with missing feet was causing water to spill out of the washer

I removed the back of the washer, removed the old water inlet syphon, replaced it with the new one, and, with some difficulty, replaced the back of the washer, reattaching all of the parts to it.

Parts Used:

-

Randy from Atlanta, GA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Wrench (Adjustable)

17 of 36 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

noisy

-

clinton from selah, WA

-

Difficulty Level:Really Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers

8 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Water Pump was leaking

The water pump had a small leak when washing clothes, and my wife was nagging me about it. I know men, youwere shocked that I said nagging and wife in the same sentence. Me being a man, I would have just left it since it is in the laundry room in the carport.

I turned the washer on its side and felt where the leak was on the pump, went inside and ordered the new pump. It was here in 2 days and it took 15 mins to put it back on with only a screwdriver to snap off the retainers and pliers to undo two hoses.

I told my woman that it was fixed and we have lived happily ever after and we played Appliance Repair Man and I was paid very well for the "House Call" if you know what I mean!!!!!

I turned the washer on its side and felt where the leak was on the pump, went inside and ordered the new pump. It was here in 2 days and it took 15 mins to put it back on with only a screwdriver to snap off the retainers and pliers to undo two hoses.

I told my woman that it was fixed and we have lived happily ever after and we played Appliance Repair Man and I was paid very well for the "House Call" if you know what I mean!!!!!

Parts Used:

-

Rick from Liberty, SC

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

9 of 13 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

No agitation, No spin, pump OK

I was familiar with the Kenmore / Whirlpool direct drive mechanism but at first I could not determine how to release the console. I finally found the end cap trim pieces would pop off revealing the 2 screws that hold the console in place. After removing them the console flips up and over the backboard. I then removed the 2 clips that hold the cabinet to the backboard, unpluged the lid switch connector and then tipped the entire cabinet forward and off the frame. This gives you access to the entire washing machine mechanism.

Next I released the 2 metal clips that hold the pump on and push it out of the way leaving the hoses connected. Next I released the 2 clips that hold the pump on, these clips also have a screw to secure them. I was then able to set the motor to the side without removing any wires.

The coupling parts had broken and were already off of the motor shaft and the input drive shaft of the transmission. I put the new drive parts on and had to tap them down untill they were flush with the end of the shafts. I then put the rubber coupling on the transmission drive end and aligned the motor drive to mate into the other holes in the coupling as I put the two back together. I then re attached the 2 motor clips with screws and reinstalled the pump with it's clips. I then reinstalled the cabinet onto the frame and replaced the cabinet clips. I then plugged in the lid switch connector and flipped the console back over and screwed it down. I then reinstalled the trim caps that had me stumped to begin with. The unit tested out OK.

Next I released the 2 metal clips that hold the pump on and push it out of the way leaving the hoses connected. Next I released the 2 clips that hold the pump on, these clips also have a screw to secure them. I was then able to set the motor to the side without removing any wires.

The coupling parts had broken and were already off of the motor shaft and the input drive shaft of the transmission. I put the new drive parts on and had to tap them down untill they were flush with the end of the shafts. I then put the rubber coupling on the transmission drive end and aligned the motor drive to mate into the other holes in the coupling as I put the two back together. I then re attached the 2 motor clips with screws and reinstalled the pump with it's clips. I then reinstalled the cabinet onto the frame and replaced the cabinet clips. I then plugged in the lid switch connector and flipped the console back over and screwed it down. I then reinstalled the trim caps that had me stumped to begin with. The unit tested out OK.

Parts Used:

-

Ernest from Midlothian, VA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

7 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Both outside door handles turned very beige

Everything worked perfectly---thanks to the suggestion of your call center agent. She suggested that since the replacement door handles were no longer available, I should consider repainting them--it worked like a charm. Please tell her she was a life saver. We rent that house in Fl and my returning tenants had complained about the discoloring refer handles. Thank you

Parts Used:

-

Howard from Boynton Beach, FL

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver

22 of 52 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!